Boiler Feed Pump Calculator

✅ Outline of the Article: “Boiler Feed Pump Calculation”

- Step 1: Introduction & Basics of Boiler Feed Pump Calculation

- Step 2: Key Parameters — Flow Rate, Head, and Efficiency

- Step 3: Pump Sizing, Selection, and Design Considerations

- Step 4: Common Engineering Calculations & Tools

- Step 5: Practical Applications, Performance Testing & Troubleshooting

Introduction & Basics of Boiler Feed Pump Calculation

🔧 What Is a Boiler Feed Pump?

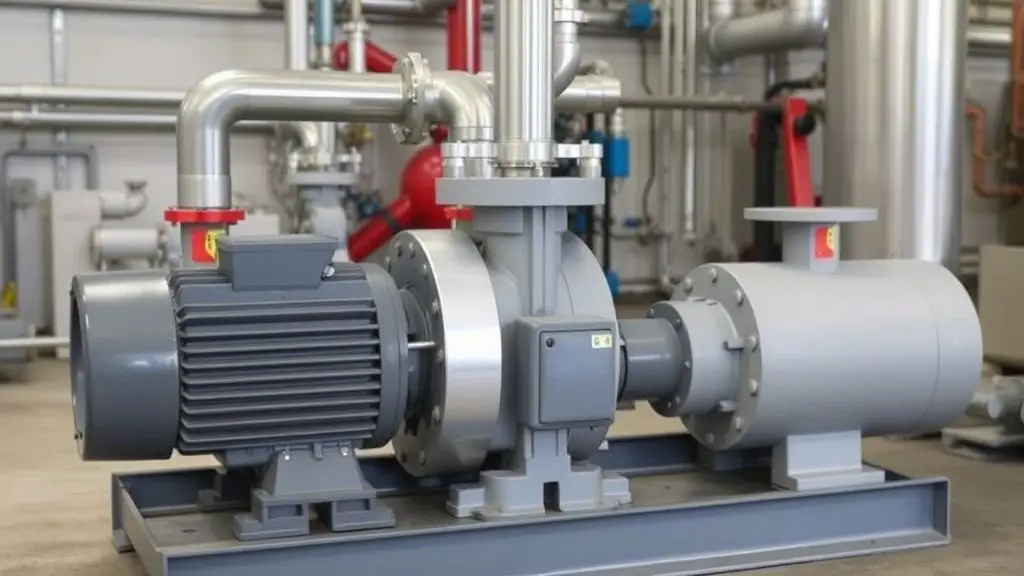

A boiler feed pump is a type of pump used to supply water into a steam boiler. The water may be newly introduced (make-up water) or it could be condensate returning from the system. These pumps are designed to operate under high pressure, often handling hot fluids at temperatures close to boiling.

In thermal power plants, chemical processing industries, and large heating systems, boiler feed pumps are considered critical equipment. Without them, the boiler can’t operate, as there’s no steady boiler feedwater flow rate to support the generation of steam.

📐 Why Is Boiler Feed Pump Calculation Important?

Designing or choosing the right pump isn’t just about selecting any motorized device to push water. You need to ensure it can handle the required flow rate, maintain the necessary discharge pressure, and function efficiently under variable conditions. That’s where boiler feed pump calculation comes in.

This calculation ensures:

- Optimal system performance

- Long pump life

- Energy efficiency

- Avoidance of problems like cavitation or pressure drop

🧮 Key Elements Involved in Boiler Feed Pump Calculation

Several factors are considered during the pump design or selection process. Let’s briefly define each one:

1. Flow Rate (Volumetric Flow Rate)

This is the amount of water the pump needs to supply to the boiler, typically measured in m³/h or GPM. The required boiler feedwater flow rate depends on boiler output capacity and load.

2. Total Dynamic Head (TDH)

The total dynamic head is the sum of the suction lift, discharge head, friction losses in the piping, and pressure requirements of the boiler. TDH is the key determinant in the pump head calculation.

3. Net Positive Suction Head (NPSH)

To avoid cavitation in boiler pumps, calculating NPSH available (NPSHa) and NPSH required (NPSHr) is crucial. NPSH is a measure of how much pressure the pump has at the suction port, and whether that’s enough to keep the water from vaporizing.

4. Pump Efficiency Factor

Pumps are not 100% efficient. The pump efficiency factor helps determine how much energy is lost in heat or friction. This is critical when performing a pump horsepower formula or power requirement calculation.

5. Discharge Pressure

Discharge pressure formula considers the required boiler pressure, elevation, and friction losses. It’s typically higher than standard water pump systems because boilers operate under high steam pressures.

⚙️ Types of Boiler Feed Pumps

There are multiple types of pumps used in boiler feedwater systems, including:

🔸 Centrifugal Pumps

Most common. They use rotational energy to move water and are ideal for high-flow, low-pressure systems. Centrifugal pump design is preferred due to simplicity and reliability.

🔸 Multi-Stage Pumps

Used when higher pressures are needed. Each stage adds more head. Common in high-pressure boiler pump systems like thermal power stations.

🔸 Positive Displacement Pumps

These are used less often but are ideal where very precise flow control is needed, though centrifugal or multi-stage pumps are more common in boiler systems.

🛠️ Boiler Feedwater System Design

The boiler feedwater system includes the pump, piping, valves, pressure sensors, flow meters, and tanks. A good system design ensures:

- Proper feed water pressure

- Smooth startup and shutdown

- Minimal pressure drop in piping

- Prevention of thermal or mechanical stress

An ideal design also accommodates a water circulation pump boiler setup where condensate can be reused efficiently.

📊 The Role of Pump Curves

Understanding pump curve interpretation is essential when selecting a pump. The curve shows:

- Flow vs. head

- Efficiency zones

- Power consumption

- NPSH requirement

By comparing pump performance test results to the pump curve, engineers can fine-tune their selection or spot problems.

📘 Common Standards & Tools

✅ ANSI Pump Standards

Pump specifications should meet industry standards like ANSI pump standards, especially in regulated industries.

✅ Calculation Tools

Today, many engineers use digital tools like:

- Boiler feed pump calculator

- Pump sizing chart

- Hydraulic pump calculation tool

- Pump design calculation Excel sheets

These resources simplify otherwise complex calculations like specific speed of pump, head loss, and flow velocity in pipe.

⚡ Real-World Example: Thermal Power Plant

In a thermal power plant pump system, the feedwater must be delivered at a pressure significantly higher than the boiler pressure. Suppose a boiler operates at 120 bar. The pump may need to deliver water at 130 bar to overcome friction losses and ensure pressure at the point of entry. Hence, boiler feed pump sizing becomes critical.

In this case, a multi-stage centrifugal pump is likely the best option, and it must be selected using detailed parameters such as:

- Pump selection criteria

- Pump sizing parameters

- Head loss calculation

- Volumetric flow rate

🔍 Common Issues Without Proper Calculation

Neglecting accurate calculation can lead to serious operational issues, such as:

- Cavitation due to improper NPSH calculation

- Pump failure due to undersized components

- Excessive power use due to low pump efficiency factor

- Flow mismatch leading to thermal shocks in the boiler

🔹 Key Parameters — Flow Rate, Head, and Efficiency

📏 1. Flow Rate (Volumetric Flow Rate)

The flow rate of a boiler feed pump defines how much water is delivered to the boiler per unit of time. It’s typically expressed in:

- Cubic meters per hour (m³/h)

- Gallons per minute (GPM)

- Liters per second (L/s)

This volumetric flow rate is a critical sizing metric in any boiler feed pump calculation, as undersized flow can cause water shortages and overheating, while oversized flow can lead to inefficiencies and pressure build-up.

💡 Formula:

Q=mρQ = \frac{m}{\rho}

Where:

- QQ = Flow rate (m³/s)

- mm = Mass flow rate (kg/s)

- ρ\rho = Density of the fluid (kg/m³)

📉 2. Flow Rate vs Pressure

There is a direct correlation between flow rate vs pressure in pump systems. As flow increases, the discharge pressure typically decreases and vice versa, as indicated in pump curve interpretation.

This relationship helps engineers decide whether to use a single-stage or multi-stage pump calculation method. For example, multi-stage centrifugal pumps are designed for cases where high pressure is needed at a lower flow rate.

📐 3. Total Dynamic Head (TDH)

Total Dynamic Head is the total equivalent height that a fluid is to be pumped, taking into account friction losses and elevation changes. This is essential in pump head calculation.

💡 TDH Formula:

TDH=Hs+Hd+Hf\text{TDH} = H_s + H_d + H_f

Where:

- HsH_s = Suction Head

- HdH_d = Discharge Head

- HfH_f = Friction Loss in piping

In most boiler feedwater system applications, TDH includes the boiler drum pressure converted into head (m), especially for high-pressure boiler pump systems.

⚙️ 4. Pump Efficiency Factor

Not all the power supplied to a pump is converted into fluid motion. Some is lost as heat or due to mechanical friction. The pump efficiency factor is a key component when determining pump power requirement.

💡 Efficiency Formula:

η=PfluidPinput×100\eta = \frac{P_{fluid}}{P_{input}} \times 100

Where:

- η\eta = Pump efficiency (%)

- PfluidP_{fluid} = Power added to the fluid (W)

- PinputP_{input} = Input power to the pump (W)

Typical centrifugal pump design efficiencies range from 65% to 85%, while older or poorly maintained pumps might drop as low as 50%.

⚡ 5. Pump Power Requirement

To estimate energy usage, engineers must calculate the pump horsepower formula or kilowatt rating for electric motor selection.

💡 Hydraulic Power Formula:

P=ρ×g×Q×HηP = \frac{\rho \times g \times Q \times H}{\eta}

Where:

- PP = Pump Power (W)

- ρ\rho = Fluid density (kg/m³)

- gg = Gravitational acceleration (9.81 m/s²)

- QQ = Flow rate (m³/s)

- HH = Total Head (m)

- η\eta = Efficiency (decimal)

This formula is the backbone of hydraulic calculation for pumps, especially for industrial boiler feed pump systems where power cost is a key concern.

🌀 6. Net Positive Suction Head (NPSH)

The NPSH calculation ensures that the pressure at the pump suction is high enough to prevent water from vaporizing. If the pressure falls below the liquid’s vapor pressure, cavitation can occur — leading to vibration, noise, impeller damage, and pump failure.

💡 NPSH Formula:

NPSHavailable=Patm+Hs−Hv−HfNPSH_{available} = P_{atm} + H_s – H_v – H_f

Where:

- PatmP_{atm} = Atmospheric pressure

- HsH_s = Suction head

- HvH_v = Vapor pressure head

- HfH_f = Friction losses in suction piping

The NPSH available must always be higher than the NPSH required, as per the pump datasheet. That’s why the mechanical seal selection and system layout are critical in preventing low-pressure zones.

🧭 7. Pipe Friction Loss

As water moves through pipes, valves, and fittings, energy is lost due to friction. This pipe friction loss is a significant component of the total dynamic head and must be included in any accurate boiler feed pump sizing.

💡 Darcy-Weisbach Formula:

Hf=f×LD×v22gH_f = f \times \frac{L}{D} \times \frac{v^2}{2g}

Where:

- HfH_f = Friction head loss (m)

- ff = Friction factor

- LL = Pipe length (m)

- DD = Pipe diameter (m)

- vv = Flow velocity (m/s)

This formula is widely used in engineering software and hydraulic pump calculation tools.

📊 8. Bernoulli Equation in Pumps

The Bernoulli equation is fundamental in fluid mechanics and helps in calculating pressure, velocity, and elevation in pumping systems. It supports detailed analysis of flow behavior and pressure changes within the boiler feedwater system.

💡 Bernoulli’s Equation:

P+12ρv2+ρgh=constantP + \frac{1}{2} \rho v^2 + \rho gh = \text{constant}

This principle can be applied to detect losses and optimize pump placement in the system.

📉 9. Specific Speed of Pump

The specific speed of pump is a dimensionless number that characterizes the geometry of a pump impeller. It helps in selecting the right type of pump for a specific flow rate and head condition.

💡 Formula:

Ns=NQ/H3/4N_s = N \sqrt{Q} / H^{3/4}

Where:

- NsN_s = Specific speed

- NN = Rotational speed (RPM)

- QQ = Flow rate

- HH = Head (m)

Lower NsN_s values are typical for multi-stage pumps, while higher values suggest axial or mixed-flow designs.

📐 10. Flow Velocity in Pipe

Choosing the correct flow velocity in pipe is important to avoid excessive friction loss or pump overwork. Typical recommendations for boiler feed systems:

- 1.5 to 3 m/s for suction lines

- 2.5 to 4.5 m/s for discharge lines

Maintaining correct velocities ensures accurate head loss calculation and reduces energy consumption.

Pump Sizing, Selection, and Design Considerations

Correct boiler feed pump sizing is essential to avoid underperformance, excessive wear, or even catastrophic failure in boiler systems. Engineers must carefully calculate and evaluate multiple variables before selecting the right pump.

📊 1. Overview of Pump Sizing Parameters

When performing a boiler feed pump sizing procedure, the following parameters are critical:

- Boiler pressure

- Flow rate (volumetric flow rate)

- Total dynamic head (TDH)

- Friction loss

- Net positive suction head (NPSH)

- Required discharge pressure

- Fluid temperature and vapor pressure

Each of these metrics is plugged into a pump sizing chart or software to help make a precise selection.

⚙️ 2. Selecting Between Pump Types

Understanding different boiler feed pump types is key to accurate selection.

🔸 Centrifugal Pumps

These pumps convert mechanical energy into kinetic energy using a rotating impeller. They are widely used for low to medium-pressure systems and are favored for their simplicity, reliability, and ease of maintenance.

🔸 Multi-Stage Pumps

When dealing with high-pressure boiler pump requirements, multi-stage centrifugal pumps are ideal. Multiple impellers in series allow for a much higher total dynamic head while maintaining a consistent volumetric flow rate.

🔸 Positive Displacement Pumps

Used less frequently in boiler feed systems, these pumps are suitable when precise, pulsation-free flow is required at high pressures. They are not common in thermal power or industrial applications but may appear in specialized systems.

🧮 3. Using a Boiler Feed Pump Calculator

An online or software-based boiler feed pump calculator simplifies the hydraulic calculation for pumps. It takes user input such as:

- Pipe diameter

- Flow rate

- Elevation difference

- Boiler operating pressure

- Efficiency

And it outputs vital data like:

- Pump power requirement

- Pump discharge pressure

- Required pump head

- Recommended impeller diameter

These tools often integrate Bernoulli equation in pumps and friction loss equations like Darcy-Weisbach.

🧠 4. Applying Pump Selection Criteria

Engineers should use structured pump selection criteria that include:

- Maximum and minimum boiler feedwater flow rate

- Startup and shutdown pressures

- Whether condensate is reused

- Pump material compatibility with treated water

- Pump curve interpretation for variable loads

- Specific speed of pump and its suitability

Selection involves more than just head and flow—it includes how the pump behaves across varying operating points.

📐 5. Pump Design Calculation Excel or Tools

For detailed analysis, engineers frequently use:

- Pump design calculation Excel sheets

- Hydraulic pump calculation tool (e.g., AFT Fathom, Pipe Flow Expert)

- CFD simulation for flow analysis

These tools aid in optimizing:

- Flow velocity in pipe

- Head loss calculation

- NPSH calculation

- Pump brake horsepower

All values must be validated against standards such as ANSI pump standards or OEM guidelines.

🛡️ 6. Mechanical Seal Selection

The mechanical seal selection process is particularly important in boiler feed pumps due to high temperature and pressure.

Key considerations include:

- Seal material compatibility with treated boiler feedwater

- Resistance to thermal shock

- Ability to handle cavitation in boiler pumps

- Pressure rating above maximum discharge pressure

Poor seal selection can result in leaks, energy loss, or even shaft damage.

🔍 7. Considerations for Condensate Recovery Systems

In systems where condensate is returned and reused, pump selection must account for:

- Lower suction head (as the water returns from various elevations)

- Higher temperatures close to saturation (risk of vaporization)

- Use of water circulation pump boiler loop to maintain feedwater reserve

This setup affects NPSH calculation, discharge pressure formula, and the need for booster pumps.

🧰 8. Thermal Power Plant Considerations

In a thermal power plant pump system, the stakes are even higher. Engineers must account for:

- High-pressure boiler pump (up to 180 bar or more)

- Large boiler feedwater flow rate (thousands of cubic meters per hour)

- Pump power requirements in hundreds of kilowatts

- Use of multi-stage pumps with stainless steel internals

- Strict compliance with standards for industrial boiler feed pump

Such systems often include emergency backup pumps, pressure control valves, and advanced pump performance test setups.

🧪 9. Margin Allowance in Sizing

Never size a pump exactly to the theoretical value. Add safety margins:

- 5–10% extra flow for variability

- 10–15% extra head for friction losses and pipe scaling

- Margin for NPSH required above calculated value

This helps avoid underperformance during peak conditions and system aging.

🛑 10. Common Mistakes in Pump Sizing

- Ignoring friction loss: Leads to underestimation of required head

- Overlooking NPSH: Results in cavitation damage

- Assuming constant flow rate: Without accounting for load changes

- Incorrect pump curve reading: Choosing a pump that runs inefficiently

- Improper seal choice: Leads to frequent leaks and failures

Avoiding these mistakes requires using correct formulas, validated tools, and experience with system dynamics.

Common Engineering Calculations & Tools

Designing and optimizing a boiler feed pump system involves a series of core engineering calculations and tools. Whether you’re working with a thermal power plant pump or a condensate return system in an industrial setting, these calculations are critical for reliability, safety, and efficiency.

🧠 1. Pump Power Requirement Formula

At the core of pump engineering lies the pump power requirement — the energy necessary to move water at a given rate and head.

💡 Formula:

P=ρ×g×Q×HηP = \frac{\rho \times g \times Q \times H}{\eta}P=ηρ×g×Q×H

Where:

- PPP = Power in watts

- ρ\rhoρ = Water density (kg/m³)

- ggg = 9.81 m/s² (gravity)

- QQQ = Volumetric flow rate (m³/s)

- HHH = Total Dynamic Head (m)

- η\etaη = Pump efficiency factor (decimal)

You may convert watts to horsepower using: HP=P746\text{HP} = \frac{P}{746}HP=746P

This formula helps determine appropriate motor sizing and energy consumption in pump sizing charts.

📉 2. Head Loss Calculation

Head loss occurs due to pipe friction, valves, fittings, and elbows. Proper head loss calculation ensures that enough pressure is available at the discharge point.

💡 Darcy-Weisbach Equation:

Hf=f⋅LD⋅v22gH_f = f \cdot \frac{L}{D} \cdot \frac{v^2}{2g}Hf=f⋅DL⋅2gv2

Where:

- HfH_fHf = Friction head loss (m)

- fff = Friction factor

- LLL = Pipe length (m)

- DDD = Pipe diameter (m)

- vvv = Flow velocity (m/s)

This data is often input into a boiler feed pump calculator for complete system design.

🔍 3. NPSH Calculation (Net Positive Suction Head)

Avoiding cavitation in boiler pumps is crucial. A common method involves calculating NPSH Available and comparing it to NPSH Required.

💡 NPSH Available:

NPSHA=Patm+Hs−Hv−HfNPSH_{A} = P_{atm} + H_s – H_v – H_fNPSHA=Patm+Hs−Hv−Hf

Where:

- PatmP_{atm}Patm = Atmospheric pressure

- HsH_sHs = Static suction head

- HvH_vHv = Vapor pressure head

- HfH_fHf = Friction in suction line

Use this with the pump datasheet values for NPSH Required to ensure safe operation.

🔁 4. Flow Rate vs Pressure Graphs

Understanding the behavior of flow rate vs pressure is essential when reading pump curves or designing a system with variable loads.

- As pressure increases, flow rate drops.

- Most pumps operate efficiently in the middle third of the curve.

- Pump curve interpretation helps visualize this relationship.

Proper use ensures pumps aren’t oversized or running against a closed valve — reducing mechanical strain and energy waste.

🌀 5. Impeller Diameter Calculation

The impeller’s size directly impacts the head generated by the pump. Sometimes, adjusting the impeller diameter is more economical than changing the motor or piping.

A simplified head estimate: H∝D2H \propto D^2H∝D2

Where DDD is the impeller diameter. Reducing diameter lowers head and flow — useful in low-load conditions.

📈 6. Specific Speed of Pump

The specific speed of pump helps classify pump types and evaluate efficiency.

💡 Formula:

Ns=N⋅Q/H3/4N_s = N \cdot \sqrt{Q} / H^{3/4}Ns=N⋅Q/H3/4

Where:

- NsN_sNs = Specific speed

- NNN = Speed (RPM)

- QQQ = Flow rate

- HHH = Head

- Low NsN_sNs → Radial centrifugal pumps

- Medium NsN_sNs → Mixed flow pumps

- High NsN_sNs → Axial flow pumps

🧰 7. Use of Hydraulic Pump Calculation Tool

Modern tools simplify these calculations significantly:

- Pipe Flow Expert

- AFT Fathom

- Pump-FLO software

- Excel pump sizing templates

These platforms allow for:

- Multi-stage pump calculation

- Real-time boiler feed pump sizing

- Scenario testing for pipe friction loss

- Optimizing flow velocity in pipe

📋 8. Pump Design Calculation Excel

Many engineers still rely on Excel spreadsheets for custom setups.

A good pump design calculation Excel includes:

- Fields for boiler pressure, TDH, flow rate

- Automatic calculation of:

- Discharge pressure formula

- Pump power requirement

- Brake horsepower

- Comparison table of boiler feed pump types

🧪 9. Bernoulli Equation in Pumps

The Bernoulli equation helps evaluate energy balance across the system — especially in horizontal and vertical layouts.

💡 General Form:

P+12ρv2+ρgh=ConstantP + \frac{1}{2} \rho v^2 + \rho gh = \text{Constant}P+21ρv2+ρgh=Constant

This equation allows calculation of:

- Pressure loss due to elevation

- Velocity head of flowing water

- Available energy for the pump

It’s foundational for hydraulic calculation for pumps in both small- and large-scale systems.

🛡️ 10. Safety Margin Calculations

It’s common to add:

- +10% Flow margin for system fluctuations

- +15% Head margin for aging and scaling

- +10–20% Power margin for load variation

- NPSH Margin of at least 0.5–1.0 m

This avoids frequent motor trips, mechanical seal selection failures, and overheating in boiler feedwater systems.

Practical Examples and Real-World Application

Understanding theory is essential, but real-world application bridges the gap between design and performance. In this section, we’ll explore how boiler feed pump calculations are applied in actual systems—ranging from power plants to industrial boilers—along with typical troubleshooting and optimization strategies.

🏭 1. Case Study: Thermal Power Plant Pump

In a 500 MW thermal power plant, high-pressure boiler feed pumps are used to deliver water into boilers operating at around 180 bar.

Key Calculations:

- Boiler Pressure: 180 bar

- Flow Rate: 450 m³/hr

- TDH (Total Dynamic Head): 2200 meters

- Pump Efficiency: 80%

Pump Power Requirement:

Using the pump power formula: P=ρ×g×Q×HηP = \frac{\rho \times g \times Q \times H}{\eta}P=ηρ×g×Q×H

After inputting values and conversions, the power requirement exceeds 750 kW, which means the pump needs to be coupled with a high-power motor, and often uses multi-stage centrifugal pumps.

🧠 Key LSI Keywords Applied:

thermal power plant pump, boiler feedwater flow rate, high-pressure boiler pump, pump power requirement, multi-stage pump calculation

🏢 2. Industrial Boiler Application Example

An industrial food processing unit uses a condensate recovery system to save energy. The boiler runs at 10 bar, and they use a centrifugal pump to circulate treated boiler feedwater.

Flow Calculation:

- Flow rate: 12 m³/hr

- Suction head: 2 m

- Friction loss: 5 m

- Required discharge head: 18 m

TDH = Suction + Friction + Discharge = 25 m

By using a boiler feed pump calculator, they chose a pump with a curve matching this requirement and added 10% for safety.

🧠 Key LSI Keywords Applied:

condensate, water circulation pump boiler, flow velocity in pipe, pump curve interpretation, treated boiler feedwater

🛠️ 3. Troubleshooting: Cavitation in Boiler Pumps

In an HVAC application, cavitation caused impeller pitting and premature seal failure.

Diagnosis:

- Low Net Positive Suction Head (NPSH)

- High water temperature near saturation point

- Insufficient elevation difference between tank and pump

Solution:

- Reduced friction by enlarging suction pipe

- Installed a booster pump

- Ensured NPSH Available > NPSH Required by 1.5 m

🧠 Key LSI Keywords Applied:

cavitation in boiler pumps, NPSH calculation, mechanical seal selection, pump suction head

📉 4. Optimization: Energy Savings via Impeller Trimming

A facility running oversized pumps faced high energy costs.

Observation:

- Pump was operating at 60% of design flow

- Operating far left of best efficiency point (BEP)

Solution:

- Applied impeller diameter calculation to trim from 200 mm to 180 mm

- Reduced power consumption by 20%

- Matched flow rate to load demand

🧠 Key LSI Keywords Applied:

impeller diameter calculation, pump efficiency, pump curve interpretation, flow rate vs pressure

📊 5. Multi-Stage Pump Calculation in Action

A chemical processing unit required high-pressure steam. A multi-stage centrifugal pump was chosen to meet the high TDH with moderate flow.

- Flow: 25 m³/hr

- TDH: 480 m

- Speed: 2900 RPM

- Each impeller added ~80 m head

- Needed: 6 stages

They used pump design calculation Excel and pump performance test to verify head per stage.

🧠 Key LSI Keywords Applied:

multi-stage pump calculation, pump performance test, high-pressure boiler pump, specific speed of pump

🧪 6. Lab Simulation: Bernoulli & Head Loss

In an academic setting, engineering students were tasked with verifying Bernoulli equation in pumps and head loss calculation using experimental rigs.

- Water was circulated through various pipe materials and diameters

- Velocity and pressure drops were recorded

- Results compared with Darcy-Weisbach equation values

🧠 Key LSI Keywords Applied:

head loss calculation, Bernoulli equation in pumps, hydraulic calculation for pumps, friction loss

🛡️ 7. Safety Consideration: Pressure Surges

An HVAC boiler system experienced pipe ruptures due to pressure surges.

Fixes Implemented:

- Installed pressure relief valves

- Sized pump using accurate discharge pressure formula

- Improved system response with variable speed drives (VFDs)

🧠 Key LSI Keywords Applied:

discharge pressure formula, pressure loss, pump sizing chart, boiler feed pump types

📋 8. Choosing the Right Pump for Condensate Recovery

When designing for a condensate return system, engineers face:

- High temperature (risk of vapor lock)

- Low suction head

- Continuous operation

Best Practices:

- Use of vertical multi-stage pumps

- Ensuring NPSH margin is adequate

- Monitoring with pump performance test

🧠 Key LSI Keywords Applied:

condensate, boiler feed pump sizing, NPSH calculation, multi-stage pump calculation

📦 9. Modern Tools in Action

Modern industries increasingly rely on:

- Hydraulic pump calculation tool for 3D pipeline analysis

- Pump design calculation Excel for on-site checks

- Digital twins for real-time performance modeling

These tools help refine pump selection criteria, especially in systems with variable loads and fluctuating pressure.